|

Combustion ChamberThe chamber is made up of firebrick materials, which can resist very high temperatures up to 1500C, as an inner wall (lining), followed by an insulating wall, which is then enclosed in a metal cage. The Bricks used are standard: 23 cm x 11.5 cm x 7.5 mm. The metal cage uses heavy duty metal plates (8-10 mm thick). The lining is applied throughout the inner parts of the chamber. |

|

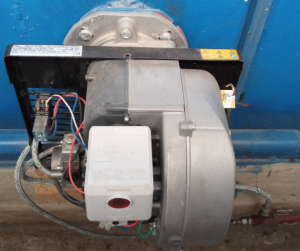

High-Efficiency & Heavy Duty Industrial BurnersThe burners installed in our system are of heavy duty industrial type, capable of raising the temperature in the chamber to the required level in a very short time (15 minutes).The burners use diesel oil as an auxiliary fuel, and when the temperature reached optimum, the photo-sensor cuts off fuel supply, thus saving on fuel oil consumption. However, it restarts automatically if the temperature falls down again. Depending on chamber size, a secondary chamber can be provided, which receives flue gas from the primary chamber and completes the combustion process, leading to cleaner flue gas. However, the heat from the secondary chamber adds up the exit heat, leading to requirements for heavy duty cooling, and hence, faster generation of hot water. |

|

Cooling System and Hot Water GenerationAs a result of high heat content in the exit gases, we have developed a hot water supply for the health facilities utilizing our technology.

The tanks must be re-filled with clean water again before another cycle can be started. |

|

Multi-Stage Scrubbing Technology for Smoke CleaningThe gases and fumes (smoke) produced during incineration are cooled in a series of heat exchangers (water cooled) and cleaned in a multi-stage wet scrubbing system. |

|

Elimination of Toxic Gaseous emissions

The remaining components are oxygen and nitrogen only, which have no hazardous effects for human health and to the environment. Because of high temperature incineration (900C), the ashes produced are completely burned without chemicals. Our organization will test the smoke exiting the scrubbing unit and provide a certificate the facility owner, for environmental auditing purposes. |

|

Contaminants in Spent WastewaterThe water is mixed with alkali, to render the pH about 12, so that the acid gases can be eliminated by neutralization reaction. The remaining solution can be discarded in the sewer once the pH drops to about 8, or when the water becomes dirty due to solids. |

|

Elimination of bad smellIncineration of biomedical waste is coupled with generation of bad-smelling fumes. The system we provide works under air tight conditions, so that all the fumes are directed to the scrubbing section. The smell is also eliminated in the same way. The water or scrubbing solution returns back to respective tanks via pipes connected from the scrubber bottom to the openings of tanks. |

|

Occupational Health and SafetyOur focus was on Occupational Health and Safety issues. The operators, together with training, they are provided with a system which is operated by using a control panel, and are not exposed to high temperatures. The combustion chamber walls are made up of firebricks and metal plates, between which there is a space filled with a heat resistant materials to prevent the outside environment from high temperatures. The process is air tight, such that there is no risk of smells and all is required is a properly working sewage system and a single phase power supply (240V/13 amps). The required operator skills are minimal, preferably Form Four leaver, who can be trained for on-off operation. The only important task is to service the burners, lessons of which are part of the training provided. |

|

Pump Station and Tank YardThe High-Tech medical waste incinerator is coupled with at least two tanks, for the purpose of:

Each tank is coupled with a single-phase pump, which is connected to the respective tank by a galvanized pipe. The power supply for pumps is through the control panel. |